Welcome to DU!

The truly grassroots left-of-center political community where regular people, not algorithms, drive the discussions and set the standards.

Join the community:

Create a free account

Support DU (and get rid of ads!):

Become a Star Member

Latest Breaking News

Editorials & Other Articles

General Discussion

The DU Lounge

All Forums

Issue Forums

Culture Forums

Alliance Forums

Region Forums

Support Forums

Help & Search

(A little late) Happy 100th anniversary, the Anaconda Copper Mining Company Smoke Stack. [View all]

It was placed into operation on May 5, 1919.

Anaconda Smelter Stack

Northwest side

Location: Anaconda, Montana

Nearest city: Butte, Montana [Anaconda doesn't count?]

Coordinates: 46°6?36.08631?N 112°54?49.51520?W

Built 1918

Architect: Alphons Custodis Chimney Constr. Co.

NRHP reference #: 87000607

Added to NRHP: April 9, 1987

The Anaconda Smelter Stack is the tallest surviving masonry structure in the world with an overall height of about 585 feet (178.3 m), including a brick chimney 555 feet (169.2 m) tall and the downhill side of a concrete foundation 30 feet (9.1 m) tall. It is a brick smoke stack or chimney, built in 1918 as part of the Washoe Smelter of the Anaconda Copper Mining Company (ACM) at Anaconda, Montana in the United States. A terra cotta coating covered the entire brick chimney when new, but by the time the smelter closed in 1981, most had eroded away except for the upper 40%, exposing most of its bricks and reinforcing rods. The inside diameter at the bottom of the brick chimney is 76 feet (23.2 m) while that at the top is about 60 feet (18.3 m). The stack and its viewing area are now the two part Anaconda Smoke Stack State Park.

....

Construction

After the concrete foundation was completed in May 1918, construction of the stack began on May 23, 1918 and was completed on November 30, 1918. It was placed into operation on May 5, 1919. It was built by the Alphons Custodis Chimney Construction Company of New York (now Hamon Custodis) under the direction of W. C. Capron, mechanical superintendent of the Washoe Smelting Company. Much of the ore the smelter processed after 1955 came from the Berkeley Pit just north of Butte, Montana. At the time it was built, the stack was the tallest masonry, brickwork structure and chimney of any kind in the world and it remains the world's tallest surviving masonry structure. Taller masonry chimneys have existed but have since been demolished. Taller chimneys that still exist are made of reinforced concrete. See List of tallest chimneys.

The Washington Monument would fit inside the stack's brick portion except for their lowest 100 feet (30 m) where an overlap of as much as one foot (0.3 m) at each corner of the monument would occur. The stack's brick portion is about 6 inches (15 cm) taller than the monument's 2015 height. The masonry portion of the stack is about 15 inches (38 cm) taller than the above ground portion of the monument's masonry, which disregards the monument's aluminum apex.

The stack was designed to discharge exhaust gases from the various roasting and smelting furnaces at the smelter. The smelter had a large network of exhaust flues from the furnaces that all fed a main flue, which carried them a half-mile south up the hill to the stack. The flue system and stack combined to provide a natural draft capable of carrying 3–4 million cubic feet (85,000–113,000 m3) per minute of exhaust gases.

State park

The Washoe Smelter was demolished after its closure in 1981. The stack alone, however, remains standing because the citizens of Anaconda organized to “Save the Stack.” It is commonly referred to as "The Stack" or "The Big Stack" and is a well-known landmark in western Montana. In 1986 it was designated the Anaconda Smoke Stack State Park. The park has two parts: the Washoe Smelter Stack Viewing Center constructed in 2000 just east of the town of Anaconda and the smoke stack about 1.2 miles (1.9 km) southeast of the viewing area. Although the site of the smelter underwent some environmental cleanup, the general public is not allowed access to the stack itself because the soil around it is still hazardous due to contamination by the toxic metalloid arsenic as well as copper, cadmium, lead and zinc. Terra cotta covered the entire surface of the chimney just as it covered its top, but by the time it closed, the bottom 60% had eroded, including the brick octagon, exposing its bricks and reinforcing rods. The terra cotta is now darker than the exposed bricks.

Northwest side

Location: Anaconda, Montana

Nearest city: Butte, Montana [Anaconda doesn't count?]

Coordinates: 46°6?36.08631?N 112°54?49.51520?W

Built 1918

Architect: Alphons Custodis Chimney Constr. Co.

NRHP reference #: 87000607

Added to NRHP: April 9, 1987

The Anaconda Smelter Stack is the tallest surviving masonry structure in the world with an overall height of about 585 feet (178.3 m), including a brick chimney 555 feet (169.2 m) tall and the downhill side of a concrete foundation 30 feet (9.1 m) tall. It is a brick smoke stack or chimney, built in 1918 as part of the Washoe Smelter of the Anaconda Copper Mining Company (ACM) at Anaconda, Montana in the United States. A terra cotta coating covered the entire brick chimney when new, but by the time the smelter closed in 1981, most had eroded away except for the upper 40%, exposing most of its bricks and reinforcing rods. The inside diameter at the bottom of the brick chimney is 76 feet (23.2 m) while that at the top is about 60 feet (18.3 m). The stack and its viewing area are now the two part Anaconda Smoke Stack State Park.

....

Construction

After the concrete foundation was completed in May 1918, construction of the stack began on May 23, 1918 and was completed on November 30, 1918. It was placed into operation on May 5, 1919. It was built by the Alphons Custodis Chimney Construction Company of New York (now Hamon Custodis) under the direction of W. C. Capron, mechanical superintendent of the Washoe Smelting Company. Much of the ore the smelter processed after 1955 came from the Berkeley Pit just north of Butte, Montana. At the time it was built, the stack was the tallest masonry, brickwork structure and chimney of any kind in the world and it remains the world's tallest surviving masonry structure. Taller masonry chimneys have existed but have since been demolished. Taller chimneys that still exist are made of reinforced concrete. See List of tallest chimneys.

The Washington Monument would fit inside the stack's brick portion except for their lowest 100 feet (30 m) where an overlap of as much as one foot (0.3 m) at each corner of the monument would occur. The stack's brick portion is about 6 inches (15 cm) taller than the monument's 2015 height. The masonry portion of the stack is about 15 inches (38 cm) taller than the above ground portion of the monument's masonry, which disregards the monument's aluminum apex.

The stack was designed to discharge exhaust gases from the various roasting and smelting furnaces at the smelter. The smelter had a large network of exhaust flues from the furnaces that all fed a main flue, which carried them a half-mile south up the hill to the stack. The flue system and stack combined to provide a natural draft capable of carrying 3–4 million cubic feet (85,000–113,000 m3) per minute of exhaust gases.

State park

The Washoe Smelter was demolished after its closure in 1981. The stack alone, however, remains standing because the citizens of Anaconda organized to “Save the Stack.” It is commonly referred to as "The Stack" or "The Big Stack" and is a well-known landmark in western Montana. In 1986 it was designated the Anaconda Smoke Stack State Park. The park has two parts: the Washoe Smelter Stack Viewing Center constructed in 2000 just east of the town of Anaconda and the smoke stack about 1.2 miles (1.9 km) southeast of the viewing area. Although the site of the smelter underwent some environmental cleanup, the general public is not allowed access to the stack itself because the soil around it is still hazardous due to contamination by the toxic metalloid arsenic as well as copper, cadmium, lead and zinc. Terra cotta covered the entire surface of the chimney just as it covered its top, but by the time it closed, the bottom 60% had eroded, including the brick octagon, exposing its bricks and reinforcing rods. The terra cotta is now darker than the exposed bricks.

The celebrating took place last year, the 100th anniversary of the stack's construction. These pictures gives you a better idea of the stack's size. I've been through Anaconda. I can confirm that you can't miss it.

A dangerous job that gave life to a town: A look back at the Anaconda Smelter

SUSAN DUNLAP susan.dunlap@mtstandard.com | Aug 8, 2018 | 12 min to read

It was hot. It was dirty. It was dangerous. But it was a job for thousands. ... Anaconda's smelter was a lifeline to immigrants and the lifeblood of a town that depended on the jobs it provided — even as the toxins it produced shortened some workers' lives.

The smelter was shut down in 1980, and the few smeltermen who are still around to tell their stories remember a different time and a very different Anaconda. One after another, the former workers of the Anaconda Company sat down with us on their front porches, on their lawns and in their living rooms and told stories of an idyllic time — kids running freely, neighbors drinking beer on the hood of their cars together, homes with huge families, and a place where people knew who lived in every house all the way down the block. A place where everybody looked out for one another. ... They remember an era when making $19.90 a day was good money and a $52 a month pension after 45 years of heavy labor was nothing to complain about. They could buy homes for $6,000, and many did.

....

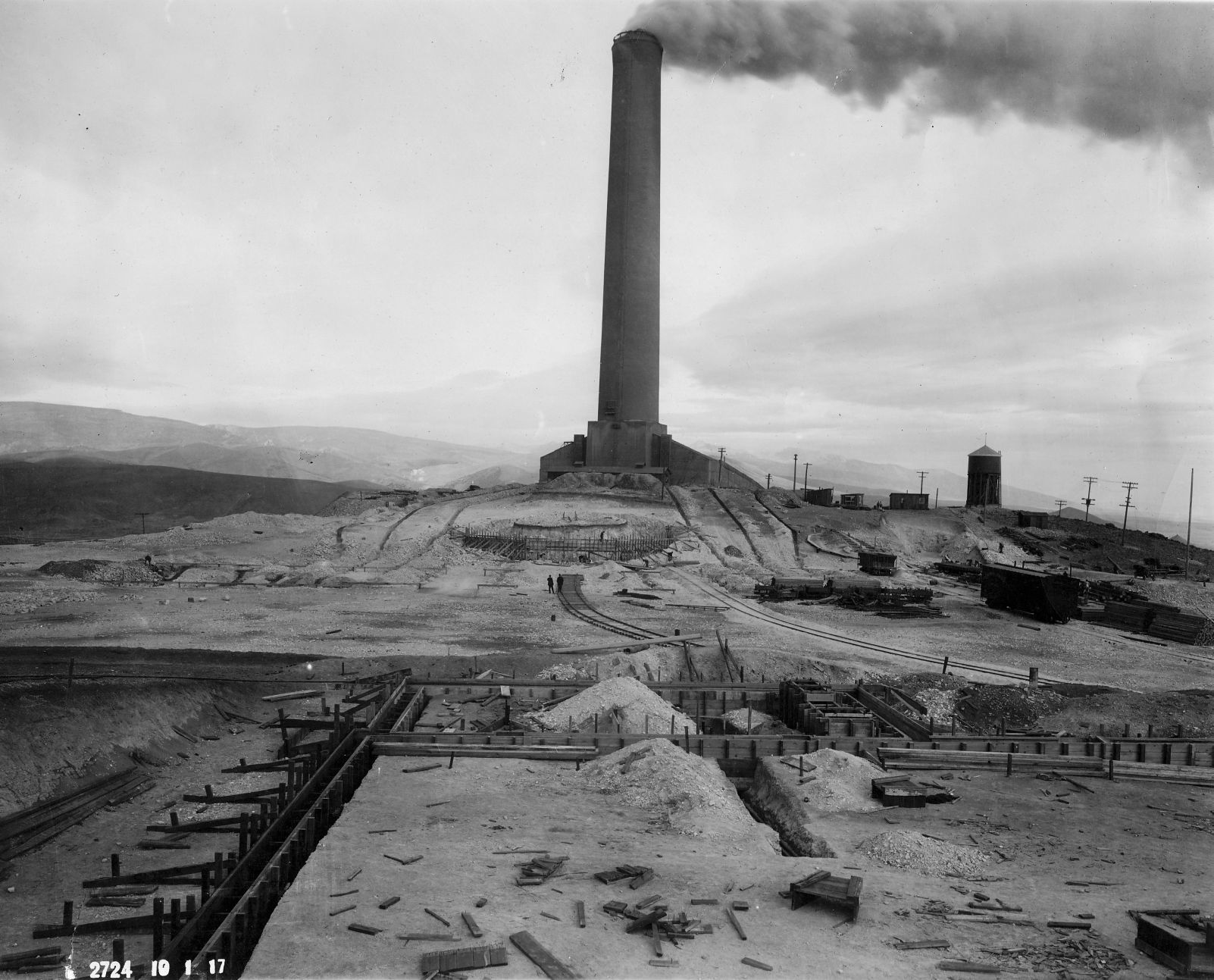

Workers put in a rail line to bring materials to the spot where the 585-foot stack would be built. The 300-foot stack sends its steady stream of smoke into the air in the background.

Photo courtesy of Copper Village Museum and Art Center

Then in 1902 the Anaconda Company moved south to build the original, approximately 300-foot stack and smelter operations near Mill Creek for a reported $9.5 million. ... But that stack wasn’t tall enough. ... Farmers and ranchers in the Deer Lodge Valley sued the Anaconda Company shortly after the first load of copper ore was smelted that year. Within that first year, livestock were dying due to the 20 tons of arsenic coming out of the stack every day.

This 1918 shot shows the beginning of the base as it was in the process of being built.

Photo courtesy of Copper Village Museum and Art Center

It took 15 more years, but in 1917, the Anaconda Company responded to the problem by preparing ground to build the 585-foot stack. The idea was a taller stack would send the arsenic farther up into the atmosphere and spread out the toxins. ... The second Anaconda Stack would also contain a pollution abatement process to capture the 75 tons of arsenic a day that was, by then, going up in smoke. The new stack and environmental control system would cost the company $1.6 million.

The system, which involved electrified chains that attracted the arsenic in the dust before it went out the chimney, was only 45 percent effective in the early years. In later years, it was somewhat improved. ... Workers alive today are familiar with that abatement system because the company continued to use it until the smelter closed in 1980. ... [Bozeman-based historian Timothy LeCain] writes in an article “The Limits of Eco-Efficiency” in a journal called Environmental History in 2000, that the company used the arsenic, a by-product of the copper smelting process, to treat railroad ties.

....

SUSAN DUNLAP susan.dunlap@mtstandard.com | Aug 8, 2018 | 12 min to read

It was hot. It was dirty. It was dangerous. But it was a job for thousands. ... Anaconda's smelter was a lifeline to immigrants and the lifeblood of a town that depended on the jobs it provided — even as the toxins it produced shortened some workers' lives.

The smelter was shut down in 1980, and the few smeltermen who are still around to tell their stories remember a different time and a very different Anaconda. One after another, the former workers of the Anaconda Company sat down with us on their front porches, on their lawns and in their living rooms and told stories of an idyllic time — kids running freely, neighbors drinking beer on the hood of their cars together, homes with huge families, and a place where people knew who lived in every house all the way down the block. A place where everybody looked out for one another. ... They remember an era when making $19.90 a day was good money and a $52 a month pension after 45 years of heavy labor was nothing to complain about. They could buy homes for $6,000, and many did.

....

Workers put in a rail line to bring materials to the spot where the 585-foot stack would be built. The 300-foot stack sends its steady stream of smoke into the air in the background.

Photo courtesy of Copper Village Museum and Art Center

Then in 1902 the Anaconda Company moved south to build the original, approximately 300-foot stack and smelter operations near Mill Creek for a reported $9.5 million. ... But that stack wasn’t tall enough. ... Farmers and ranchers in the Deer Lodge Valley sued the Anaconda Company shortly after the first load of copper ore was smelted that year. Within that first year, livestock were dying due to the 20 tons of arsenic coming out of the stack every day.

This 1918 shot shows the beginning of the base as it was in the process of being built.

Photo courtesy of Copper Village Museum and Art Center

It took 15 more years, but in 1917, the Anaconda Company responded to the problem by preparing ground to build the 585-foot stack. The idea was a taller stack would send the arsenic farther up into the atmosphere and spread out the toxins. ... The second Anaconda Stack would also contain a pollution abatement process to capture the 75 tons of arsenic a day that was, by then, going up in smoke. The new stack and environmental control system would cost the company $1.6 million.

The system, which involved electrified chains that attracted the arsenic in the dust before it went out the chimney, was only 45 percent effective in the early years. In later years, it was somewhat improved. ... Workers alive today are familiar with that abatement system because the company continued to use it until the smelter closed in 1980. ... [Bozeman-based historian Timothy LeCain] writes in an article “The Limits of Eco-Efficiency” in a journal called Environmental History in 2000, that the company used the arsenic, a by-product of the copper smelting process, to treat railroad ties.

....

CALENDAR OF EVENTS

Anaconda stack 100th Anniversary celebration calendar of events

Aug 8, 2018

STEVEN CORDES, THE MONTANA STANDARD

Anaconda stack 100th Anniversary celebration calendar of events

Aug 8, 2018

STEVEN CORDES, THE MONTANA STANDARD

2 replies

= new reply since forum marked as read

Highlight:

NoneDon't highlight anything

5 newestHighlight 5 most recent replies

= new reply since forum marked as read

Highlight:

NoneDon't highlight anything

5 newestHighlight 5 most recent replies

(A little late) Happy 100th anniversary, the Anaconda Copper Mining Company Smoke Stack. [View all]

mahatmakanejeeves

Jun 2019

OP